IMPLEMENTATIONS OF CLEANROOMS

BLOCK® modular systems for built-ins cleanrooms.

Cleanrooms Compliant with cGMP and FDA Regulations

Pharmaindustrie, Biotechnologie, Medizintechnik

Forclean® GMP System

For the construction of cGMP and FDA compliant cleanrooms where the crucial parameter is the prevention of particulate and microbial contamination.

Own development and manufacture within the BLOCK® Holding.

More infoCleanrooms for Healthcare

Medical Departments

Formedical® System

BLOCK Surgical® System

Forclean® GMP System

Own development and manufacture within the BLOCK® Holding.

Choose systemIndustrial Cleanrooms

Microelectronics, Optics, Automotive Industry

Forclean® Industry System

Cleanrooms for the sector of use, where the crucial parameter is the prevention of particulate contamination, which negatively affects the technological process and quality – reliability of the product.

Own development and manufacture within the BLOCK® Holding.

More infoBLOCK® modular systems for medical departments.

Formedical® System

Medical Departments

Formedical® System

Designed for the construction of all types of medical facilities where the cleanliness of the environment and a simple design are important. Asepsis, patient and staff protection, technology innovation and space design are crucial parameters in these facilities.

Own development and manufacture within the BLOCK® Holding.

More infoBLOCK Surgical® System

Operating Theatres

BLOCK Surgical® System

Designed for the implementation of operating theatres. The wall system is based on a horizontal division of panels. The centre and bottom parts are thus removable. It allows an easy integration of technology, cabinets and other parts whenever needed.

Own development and manufacture within the BLOCK® Holding.

More infoForclean® GMP System

Čisté prostory podle pravidel cGMP a FDA - Laboratoře | Tkáňová centra

Forclean® GMP System

For the construction of cGMP and FDA compliant cleanrooms where the crucial parameter is the prevention of particulate and microbial contamination.

Own development and manufacture within the BLOCK® Holding.

More infoCLEANROOMS ON A TURNKEY BASIS - BLOCK® COMPLETE SERVICES

We have our own teams of top experts with experience since 1991 for the individual phases of implementation.

CLEANROOM CONSTRUCTION – BLOCK® MODULAR BUILT-INS

Cleanroom is solved as a assembled modular built-in into the existing building. The very term “built-in“ simply means a space withing a space. For cleanroom built-ins we develop and manufacture, within the BLOCK® Group, our own systems: Forclean® GMP System, Forclean® Industry System, BLOCK Surgical® System, Formedical® System. These systems consist of mutually compatible structural components and are highly variable and flexible.

Cleanroom Components

- Wall Systems

- Wall Systems Glazing

- Doors and their Accessories

- Suspended Ceiling Systems

- Floors

- Lamps

- Covings and their Accessories

- HVAC Components

- Built-in Furnishings

- Accessories

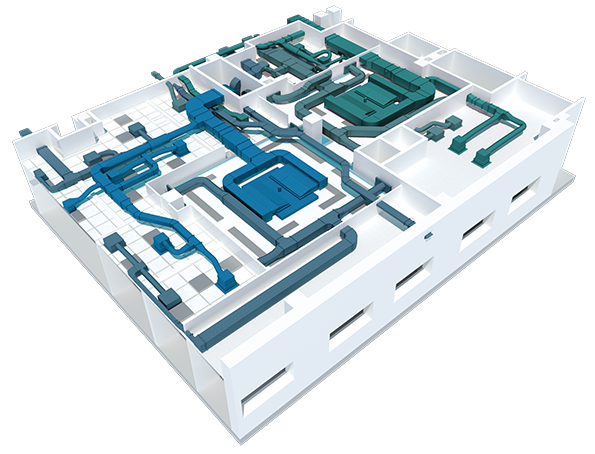

CLEANROOM AS A FUNCTIONAL UNIT

Cleanroom is not just the cleanroom built-in itself. It’s a functional unit consisting of built-ins, HVAC, internal distribution networks, technologies and furnishings. When implementing a celanroom on a turnkey basis we will supply you with all these sub-components. The result for you will be a fully functional clean space, ready for full operation.

Cleanroom built-ins

For cleanroom built-ins we offer our own systems: Forclean® GMP System, Forclean® Industry System, BLOCK Surgical® System, Formedical® System.

HVAC (Heating, Ventilation, Air-conditioning, Refrigeration)

The most important part of a cleanroom is HVAC. In general, the task of HVAC is to protect the personnel, the product and the surrounding environment.

Air intake is provided by a central air-conditioning unit with total treatment of the supplied air. The components at the end of HVAC are a part of the cleanroom built-ins – they’re built into the walls and the ceiling.

The greatest emphasis is placed on the purity of the supplied air, which is ensured by a three-stage filtration with a final HEPA or ULPA filter.

Technological distribution of media and product pipelines

- Clean media PW, WFI, PS

- Process gases and other process media

- Industrial steam

- Waste Management

- Product Pipelines

- CIP-SIP stations

- Media and medical gases in the healthcare sector

Wiring, Measurement and Regulation Systems (MaR)

We offer complex delivery of Measurement and Regulation Systems (MaR) for all inner building systems:

- A/C Systems

- Building and Technology Refrigeration Systems

- Heat Exchanger Units

- Special applications customized to the end-user

Process and medical technologies

- Our room solution also includes the delivery of technological equipment. For delivery we cooperate with certified technology specialists. We have a highly qualified team of workers for the design, assembly, operationalization and validation of even the most complex technologies.

Isolator technology

The manufacturer and supplier of isolator technology is our partner company BLOCK Technology which is also a member of the BLOCK® Group. The main specialization of BLOCK Technology is the custom production of isolator technology. Other than that BLOCK Technology also offers standard lines of isolators.

Appliances, Equipment and Videomanagement

For delivery we cooperate with verified and reliable suppliers.

Furnishings, Stainless Steel Furnishings

Stainless steel furnishing for cleanrooms is produced by our partner company Forclean, which is also a member of the BLOCK® Group.

ADVANTAGES

System compatibility

The individual components of the BLOCK systems are mutually compatible – a. k. a. EASY TO ASSEMBLY trend. Thanks to this, it is possible to assemble any room of the highest quality.

Years of experience and flexibility

With our many years of experience and flexibility, we can respond to current trends and meet specific customer requirements. On the market we are known for being able to meet even the most demanding requirements for clean rooms.

In-house development and production

We develop and manufacture the individual components of all systems ourselves – therefor it is not a problem for individual components to adapt to specific space requirements.

Simple integration

BLOCK systems offer a simple integration of the relevant technology and equipment according to the project documentation solution.

Precise details

During production and assembly, we put emphasis on high-quality processing of details, which are essential for rooms demanding environmental quality.

Easy to clean

Cleanrooms built from BLOCK systems are easy to clean: sealed joints, covings, smooth transitions.

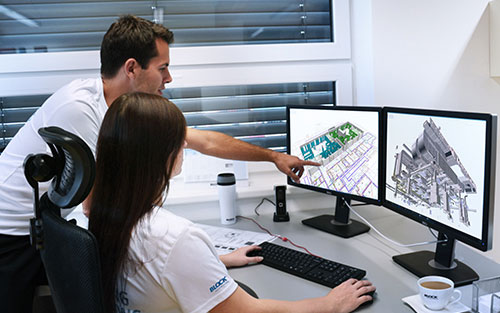

BIM - BUILDING INFORMATION MODELING

Since 2015 we have been processing project documentation in models using the BIM methodology. We also use the BIM methodology during the construction itself and step by step we carry it out into all other phases of the implementation.